Top 10 the most common questions about Progressive Cavity Single Screw Pumps.

What is a progressive cavity pump, and how does it work?

A progressive cavity pump is a type of positive displacement pump that operates through the interaction of a helical rotor and a stator. The rotor, a screw-like component, fits within the stator, a tube with a matching internal profile. As the rotor turns within the stator, a series of sealed cavities form and progress from the inlet to the outlet side of the pump. This action displaces fluid, creating a continuous and gentle flow. The pump's design allows it to handle a wide range of viscosities, making it suitable for transferring fluids from thin liquids to thick pastes, while its positive displacement nature ensures consistent performance even with challenging materials like abrasive slurries or highly viscous substances.

What are the advantages of using progressive cavity pumps?

Using progressive cavity pumps offers several advantages across industries: they excel in transferring fluids with varying viscosities, from low to high, maintaining product integrity; their gentle, non-pulsating flow is ideal for shear-sensitive materials; they handle fluids containing solids or abrasives effectively; self-priming capability streamlines operations; accurate dosing is possible for precise applications; and their adaptability spans industries such as wastewater treatment, oil and gas, and food processing.

Where are progressive cavity pumps commonly used across industries?

Progressive cavity pumps find wide application across diverse industries: in wastewater treatment, they handle sludge and chemicals; in the oil and gas sector, they transfer viscous crude oil and drilling mud; the food and beverage industry uses them for gentle handling of sauces and purees; mining relies on them for abrasive slurries and viscous materials; the chemical industry benefits from their ability to handle corrosive chemicals; the pulp and paper industry employs them for paper pulp and additives; marine operations utilize them for bilge water and fluids; the biogas industry employs them in handling organic waste; and the construction field relies on them for grouts, coatings, and slurries, demonstrating their versatility and essential role in various sectors.

How do progressive cavity pumps handle high-viscosity fluids and solids?

Progressive cavity pumps excel in handling high-viscosity fluids and solids due to their unique design: the helical rotor and stator combination creates sealed cavities that trap and progressively move the fluid or solids. As the rotor turns within the stator, the cavities decrease in size, compressing the material and generating the pressure required for movement. This design minimizes shear forces, enabling the pump to gently and efficiently handle high-viscosity fluids without compromising product quality. Additionally, the pump's design accommodates solids by preventing clogging; the cavities' self-cleaning action and minimal clearance between rotor and stator ensure effective transportation of solids-laden fluids, making progressive cavity pumps suitable for applications involving slurries and materials with suspended particles.

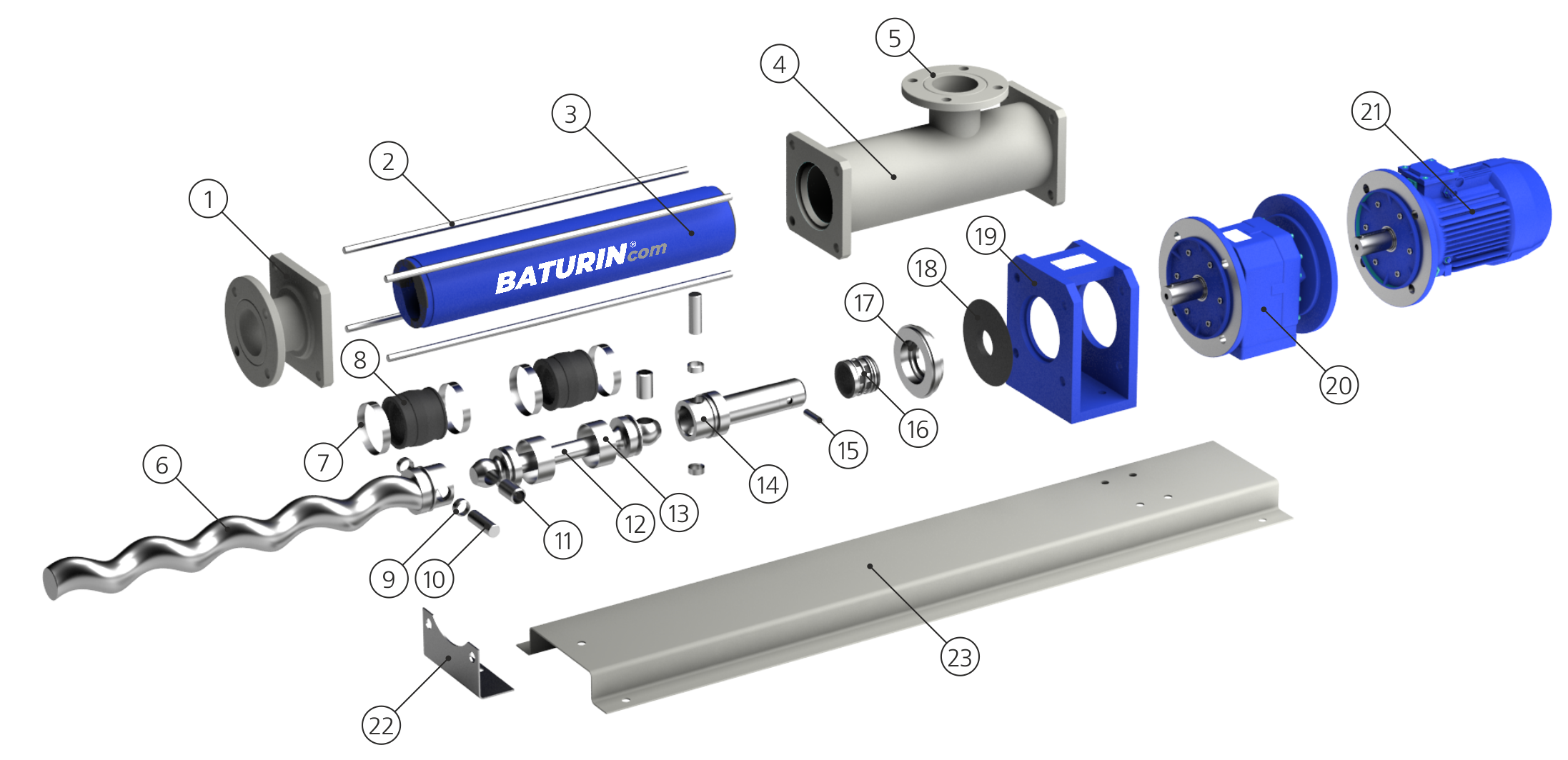

What are the main components of a progressive cavity pump?

The main components of a progressive cavity pump include a helical rotor and a stator. The rotor, resembling a screw, is a central shaft with helical threads that fit into the stator, a cylindrical tube with a matching internal profile. Together, these components create sealed cavities that progress from the pump's inlet to outlet side as the rotor turns within the stator. Other essential elements include bearings that support the rotor's rotation, shaft seals to prevent fluid leakage along the shaft, inlet and outlet ports for fluid entry and exit, a drive mechanism often in the form of an electric motor, and a coupling connecting the drive to the pump's shaft. These components collectively facilitate the pump's positive displacement action and efficient transfer of fluids, while additional features like a hopper and feed screw can aid in pumping solids or viscous materials.

How do you select the right progressive cavity pump for a specific application?

Selecting the right progressive cavity pump for a specific application involves considering key factors such as the nature of the pumped fluid, its viscosity, solids content, corrosiveness, temperature, flow rate, and pressure requirements. Evaluating the pump's material compatibility with the fluid is essential to ensure durability. Additionally, assessing the need for special features like hopper feeding or explosion-proof designs, along with the space available for installation, helps tailor the pump to the application's unique demands. Collaborating with pump manufacturers or experts to analyze these parameters aids in choosing the appropriate pump size, configuration, and materials that best match the requirements of the intended application, ultimately optimizing performance and efficiency.

What maintenance and servicing are required for progressive cavity pumps?

Maintenance and servicing for progressive cavity pumps include regular inspection of rotor and stator wear, replacement of components when necessary, and lubrication of bearings and seals. Cleaning and flushing of the pump to prevent buildup and clogging are vital, particularly when handling solids or abrasive materials. Monitoring shaft seals and checking for leakage helps maintain pump efficiency. Ensuring proper alignment and tension of belts, if applicable, contributes to smooth operation. Additionally, adhering to manufacturer-recommended maintenance schedules, training personnel on proper operation, and addressing any issues promptly are essential practices to extend pump lifespan and sustain optimal performance.

Can progressive cavity pumps handle corrosive or abrasive fluids?

Yes, progressive cavity pumps are capable of handling both corrosive and abrasive fluids due to their unique design. The close tolerances between the rotor and stator prevent contact between the pumped fluid and the pump's metal components, reducing the risk of corrosion. Additionally, the gentle and consistent flow provided by progressive cavity pumps minimizes the impact of abrasive particles on the pump's internal surfaces. By selecting appropriate materials for the rotor, stator, and other components, and ensuring proper maintenance practices, progressive cavity pumps can effectively handle fluids with corrosive properties and abrasive content, making them suitable for applications in industries such as chemical processing, mining, and wastewater treatment.

What is the efficiency and energy consumption of progressive cavity pumps?

The efficiency of progressive cavity pumps can vary based on factors such as fluid viscosity, pressure requirements, and pump design. Generally, these pumps offer high volumetric efficiency and consistent flow, making them well-suited for applications requiring accurate dosing and handling of shear-sensitive materials. However, their efficiency can decrease at lower speeds or when handling highly viscous fluids. Energy consumption is influenced by the pump's size, speed, and operating conditions. While progressive cavity pumps may require more energy than some other pump types due to their positive displacement nature, they excel in handling challenging fluids, ultimately contributing to efficient and reliable fluid transfer in a wide range of industries.

How does the choice of materials impact the performance of progressive cavity pumps?

The choice of materials significantly impacts the performance of progressive cavity pumps. The compatibility of materials with the pumped fluid determines factors such as corrosion resistance, wear resistance, and overall durability. Using the right materials ensures that the pump can handle corrosive chemicals without degradation or contamination, and it can transfer abrasive fluids without excessive wear on the rotor and stator. Material selection also influences the pump's ability to handle different temperature ranges and maintain its efficiency over time. Additionally, proper material choices prevent reactions that could alter the fluid's properties and negatively affect pump performance. By selecting materials that align with the specific characteristics of the pumped fluid, the pump can deliver reliable and efficient performance while extending its operational lifespan.